What is Working Load?

WORKING LOADS

HOW TO WORK THEM OUT

To help our customers develop their own safety strategies, we apply the terminology “Working Load” to the full range of our suspended equipment. The term "Working Load" represents the maximum sustainable load that the equipment has been designed to bear, it is NOT the number at which the equipment will fail.

It is important to remember that “Working Loads” differ from Static Loads, as “Working Loads” take “Movement Forces” into consideration.

GROSS WEIGHTS

To help you calculate the “Working Load”, you first need to work out the “Gross Weight” of the user and equipment. To do this you need to combine the weight of the user and/or therapist, the equipment and any other ancillary equipment which will be placed on the equipment in order to gain the “Gross Weight”.

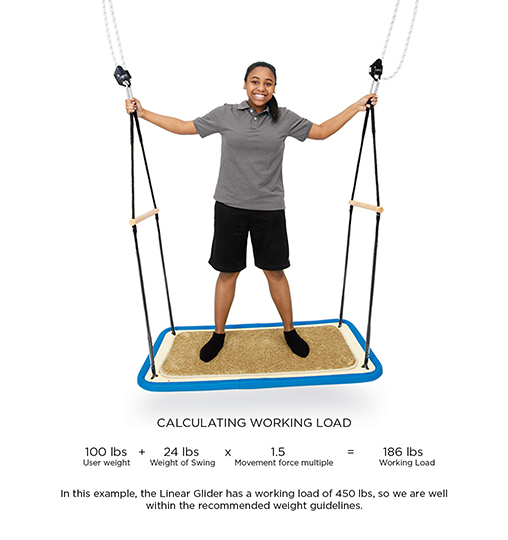

E.g. User (100 lbs) + Linear Glider (24 lbs) = Gross Weight (124 lbs).

MOVEMENT FORCES

Once you have this “Gross Weight”, we can now start to work out what the “Movement Forces” will be. A good example of this force can be done very simply at home: If a user of 100 lbs jumped on a set of scales, they would see the reading to momentarily go much higher than the 100 lbs they weigh, due to the “Movement Forces”. These therefore need to be taken into consideration when working out whether your therapy will remain within the recommended “Working Loads”.

Depending on the activity the therapist and user are conducting, these “Movement Forces” will change considerably. For example, in studies conducted into the “Movement Forces” placed on trapeze artists, the ratios of the users weight to maximum force generated can be over a multiple of 4! Based on this the Total Gross Weight of the User and swing (124 lbs) would be more like 496 lbs, thus exceeding the Working Load of the Linear Glider.

HOW THIS APPLIES TO SENSORY INTEGRATION THERAPY

We understand that Sensory Integration therapy would most likely not generate these levels of force, so in conjunction with industry experts, we normally state that up to 2 times Gross Weight would be a sufficient guide for most activities. This obviously reduces proportionally if movement is reduced. The below calculation therefore would need to be done:

E.g User (100 lbs) + Linear Glider (24 lbs) x Movement force multiple (1.5) = Working Load (186 lbs). The Linear Glider in this example has a “Working Load” of 450 lbs, so this would be well within the recommended weight guidelines.

WHAT DO I DO IF I EXCEED?

A lot of our customers ask, what if we exceed these amounts? First, we would recommend that you don’t, as we offer a wide range of swings with varying weight limits and we would assist you to help you choose the best swing for your needs. However, slight overages on the Working Load will not mean the product will necessarily fail. All our swings have been Mechanically weight tested to levels far exceeding the listed “Working Loads”. The Linear Glider for example, exhibited signs of failure at a “Static Load” of slightly over 2,300 lbs! This is based on test conditions and even weight distribution.

OUR "SAFETY" FACTOR

We do allow a “Safety Factor” when choosing our listed “Working Loads” and we allow a “Safety Factor” of 5. This means that when a swing shows failure at an applied “Static Load”, we divide this number by 5 to give a “Working Load” (with slight differentiations for rounding up/down).

E.g. Linear Glider “Static Load” Failure Weight (2,300 lbs) / “Safety Factor” (5) = Linear Glider Working Load (460 lbs)

KEEPING YOUR EQUIPMENT MAINTAINED

Ultimately remaining within these working loads is the best way to prolong the life of the equipment and ensure that any condition warranty is eligible. It does not exempt the product from regular maintenance, cleaning and correct use, please see Safety Tips on how to set up your own maintenance schedule.

On all of our equipment, we clearly state that the equipment is for non recreational activities and are not designed for unsupervised play. However, we understand that some customers will still do this. Use in this manner will potentially void any warranty as we have seen in cases such as this that the Total Gross Weight can be multiplied by 3, putting a lot more pressure on the swing.

CONCLUSION

To conclude, Southpaw equipment can be viewed as you would a car - the more miles you put on it and the faster you drive, it will need for more oil changes, more maintenance, repair and cleaning. This is exactly the same for our equipment, if you are consistently reaching the maximum working loads on a consistent basis, then it would be expected that this equipment would not last as long as one which is being used lightly and infrequently.

All in all, the importance of a thorough risk assessment and a proper, scheduled maintenance program cannot be overstated.